Since the method begins with an understanding of the form errors introduced into the part by the particular manufacturing regime, at least partial benefit can be seen even when the sample pattern optimization is employed in conjunction with commercial, off-the-shelf CMM control and data analysis software. These are values on a linear calibrated scale but not relative to a true zero point in time or space.

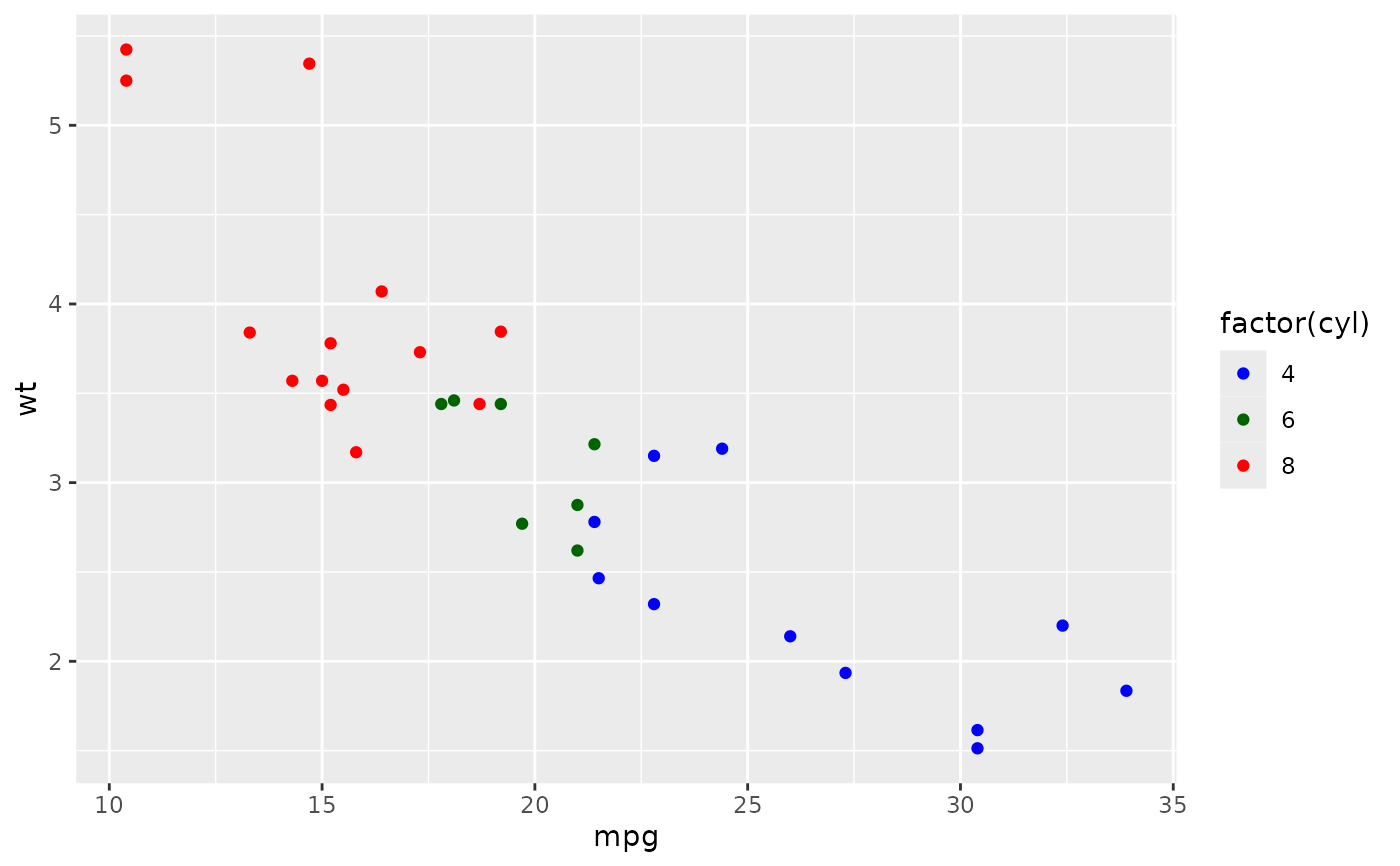

In contrast to most work on these problems, extensive use is made of process-dependent information in selection of sampling protocol and data analysis method. Its application does, in many cases, produce significant improvements in the uncertainty of derived geometric dimensioning and tolerancing parameters with modest or no increase in measurement time. As a recap, discrete effort is the name given to the work required for an activity that can be planned, measured and ends up with. Practice Exercise 5: Interval variables: No Response Name. Today I’m going to share the other two options: weighted milestone and physical measurement. On the Fahrenheit scale, 0 is 32 degrees below the freezing point of water. And Numerical Data can be Discrete or Continuous: Discrete data is counted, Continuous data is measured. The technique is, however, of general utility and can be employed with any nominal feature geometry. In Part 1 of this article I talked about two ways to measure discrete effort: percent complete and fixed formula. Data can be Descriptive (like 'high' or 'fast') or Numerical (numbers). Nominal Scale : This is a figurative labeling scheme in which the numbers serve only as labels or tags for identifying and classifying objects.

#POINT MEASURE DISCRETE FULL#

The focus of the work reported here is on full internal cylindrical surfaces. There are four primary scales of measurement : nominal, ordinal, interval and ratio. Interval Scale : In an interval scale, scale represents equal distance between the values in the characteristic being measured. In this report, these mathematical tools are further developed and applied for the determination of optimum, reasonably-sized probing patterns for measurement under time and economic constraints. A recent report described the development of new techniques for modeling the form errors of machined part features and illustrated their use in identifying and understanding the relation of form errors to machining process variables.

These are data that can be counted, but not measured. Selection of an appropriate sampling strategy and of the correct fitting algorithm are two of the key issues in the practice of modern coordinate metrology. Discrete data are a type of quantitative data that can take only fixed values.

0 kommentar(er)

0 kommentar(er)